The expression of the amount of moisture in wood is as a percentage of the weight of the wood. This is especially when there is the use of the oven-drying method. When a tree is still growing, the tree may have more moisture in it than oven-dry wood fiber. As a result, the moisture contents become greater than 100%. Upon cutting and exposure to air, the moisture dries from the wood.

In a sawmill, the kiln process exposes the wood to elevated temperatures to aid the drying process. Southern Pine lumber can be grade stamped as KD19 after drying in a kiln to a maximum moisture content of 19%. This generally means that the average moisture content of the lumber will be close to 15%, with some pieces somewhat drier and some pieces somewhat wetter.

Why dry lumber?

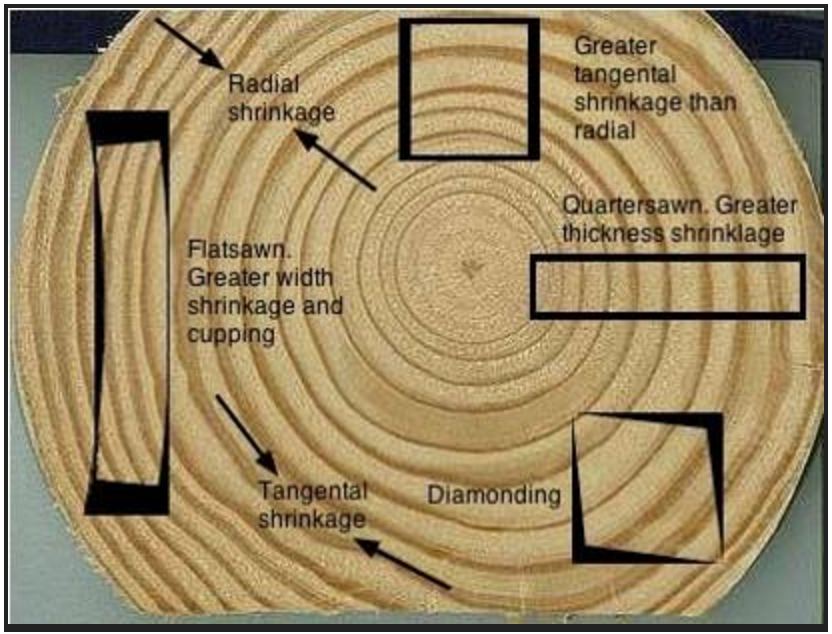

When mills dry their lumber, it reduces the weight of the product which reduces shipping costs. Drying lumber also tends to increase the strength and stiffness properties. As wood loses moisture content, it will also shrink in size. In fact, as the wood dries below about 30% moisture content, it will lose about 1% in the radial and tangential directions for every 4% drop in moisture content. Wood shrinks very little in the longitudinal (lengthwise) direction as it dries. The picture below shows exaggerated images of how lumber shrinks relative to where it was cut from the log.

When wood is used in a structure, it will equilibrate to the moisture content determined by the ambient relative humidity. In the US, this can vary from about 6% MC in arid regions to about 11% MC in coastal regions. Much of the country is however at about 8% MC. The closer a piece of lumber is to the moisture content it will equilibrate to in place means the less shrinkage will occur after its installation. If the moisture content of wood exceeds about 23%, it may begin to mold. Keeping lumber mold-free is another good reason to dry lumber.