OSHA planks, also known as OSHA-compliant scaffold planks, are specialized wooden planks designed to meet the stringent safety standards set by the Occupational Safety and Health Administration (OSHA) for use in scaffolding. These planks are an essential component in construction and industrial settings where scaffolding is required. They provide a safe, stable platform for workers operating at elevated heights, ensuring that the scaffolding structure can support the necessary weight without compromising safety.

Materials and Construction

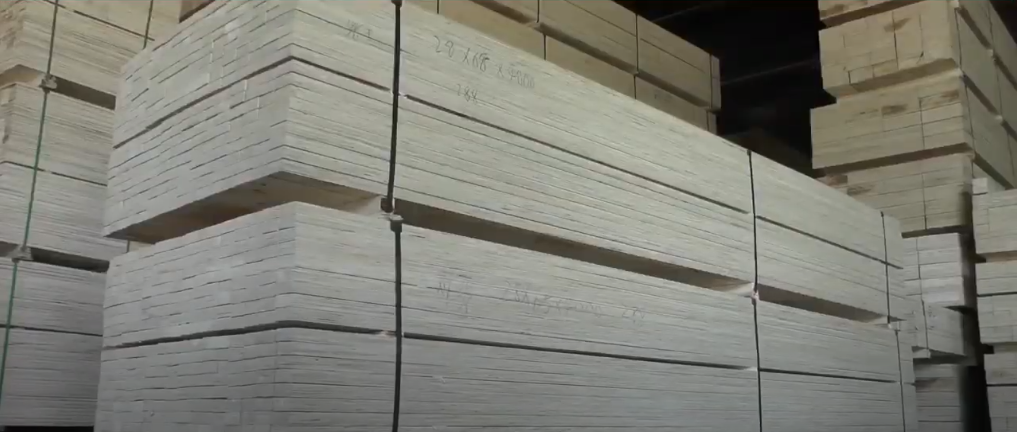

OSHA planks are typically made from high-quality, dense wood, such as Southern Yellow Pine, which is known for its strength and durability. The wood is carefully selected and graded to meet specific standards that ensure the planks can withstand heavy loads and harsh working conditions. The planks are usually kiln-dried to a precise moisture content to prevent warping, cracking, and other issues that could compromise their structural integrity.

Safety Standards and Compliance

To be OSHA-compliant, these planks must meet strict guidelines regarding their dimensions, load-bearing capacity, and overall quality. The planks are required to support a minimum of four times the intended load, including both the weight of workers and any tools or materials they are using. Additionally, OSHA planks must be inspected regularly for signs of wear, damage, or defects that could pose a safety risk. Any plank that does not meet the necessary standards must be removed from service immediately.

Applications

OSHA planks are widely used in various construction and industrial applications, including building construction, maintenance, and repair work. They are essential for scaffolding setups, where a stable and reliable platform is critical for worker safety. These planks are not only used for supporting workers but also for holding tools, materials, and equipment, making them a versatile component in many job sites.

Inspection and Maintenance

Regular inspection and maintenance of OSHA planks are crucial to ensuring ongoing safety. Before each use, workers should inspect the planks for any signs of damage, such as cracks, splits, or excessive wear. Planks that show any signs of compromise should be replaced immediately. Proper storage of planks, away from excessive moisture or harsh environmental conditions, can also extend their lifespan and maintain their safety.

Conclusion

OSHA planks are a critical element in the construction and scaffolding industry, providing a safe and stable platform for workers. Meeting stringent OSHA standards, these planks are designed to support heavy loads and withstand challenging conditions, ensuring worker safety at elevated heights. Regular inspection and proper maintenance are key to preserving the integrity and safety of these essential tools. Sherwood Lumber offers high-quality OSHA-compliant planks to meet the rigorous demands of your construction projects.