These three are all similar in that they all are separations lengthwise in the grain of the wood; however, each has a different origin and a different effect on the grade of dimension lumber. First, let’s look at the definition of each.

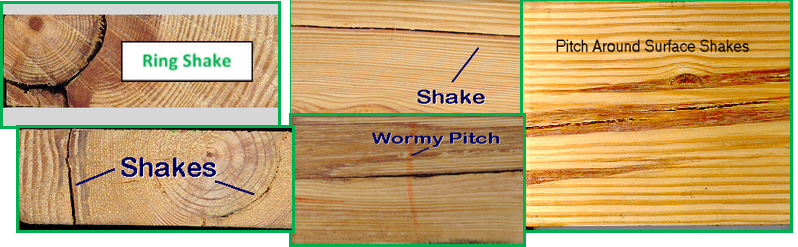

Shakes

Shakes are a defined lengthwise separation of the wood along the grain, usually occurring between or through the rings of annual growth. A surface shake occurs on only one surface, while a through shake extends from one side to the opposite or adjoining side of the piece.

Shakes are natural occurring defects in standing trees caused by a lengthwise separation of latewood fibers. Shakes were once thought to be caused by external stress factors such as wind and temperature extremes (often called wind shakes); however, research has found that a bacterium is the true cause of shake. The bacteria that causes shake enter the trees through the roots and not through the stem. The bacterium belongs to the clostridium genus and is often accompanied by an unpleasant odor.

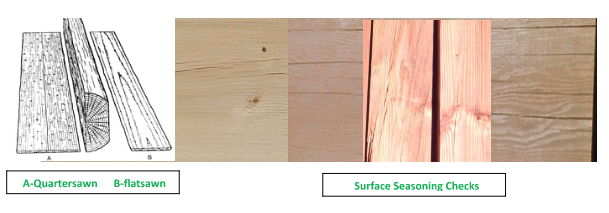

Checks

Checks are a separation of the wood normally occurring across or through the rings of annual growth and usually as a result of seasoning. Surface checks are failures that usually occur in the wood rays on the flatsawn faces of boards.

Checks occur because drying stresses exceed the tensile strength of the wood perpendicular to the grain, and they are caused by tension stresses that develop in the outer part, or shell, of boards as they dry around the still wet and swollen core. Surface checks can also occur in resin ducts and mineral streaks. Surface checks usually develop early in drying because the lumber surfaces dry too quickly as a result of low relative humidity.

End checks occur because moisture moves much faster in the longitudinal direction than in either transverse direction. Therefore, the ends of boards dry faster than the middle and stresses develop at the ends.

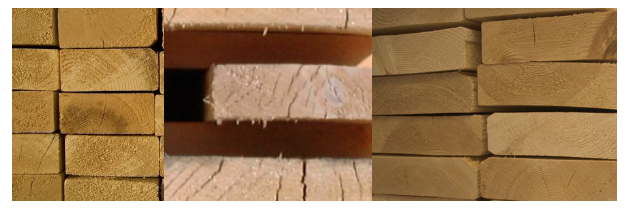

Splits

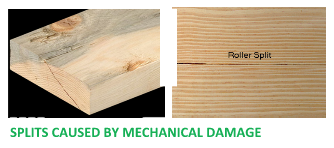

They are a separation of the wood through the piece to the opposite surface or to an adjoining surface due to the tearing apart of the wood cells. Splits in wood are sometimes the result of the drying process or the dry kiln. Splits caused by drying extend across one or more growth rings (radial direction). Many splits extend parallel to the growth ring, as in the case of mechanical damage, while some splits run at various angles to the grain and growth rings.

A Roller Split is a crack in the wood structure caused by a piece of cupped lumber being flattened in passing between the machine rollers.

End splits are often caused by growth stresses and are therefore not a drying defect. End splits can be present in the log or sometimes develop in boards immediately after sawing from the log. Splits that are the result of drying ruptures occur in the radial direction. In all drying defects, (end splits, surface checks, and end checking or splitting) the rupture will extend across one or more growth rings.

End splits are often caused by growth stresses and are therefore not a drying defect. End splits can be present in the log or sometimes develop in boards immediately after sawing from the log. Splits that are the result of drying ruptures occur in the radial direction. In all drying defects, (end splits, surface checks, and end checking or splitting) the rupture will extend across one or more growth rings.

Shakes, Checks and Splits and the grade of dimension lumber

A relatively small amount of splits, checks, or shakes are acceptable under the grading rules for dimension lumber . The allowed amount varies by grade. The amounts allowed are based upon the effect that these defects have on various strength properties of wood.

Because shakes and splits reduce resistance to shear in members subjected to bending, the grading rules restrict shake most closely in those parts of a bending member where shear stresses are highest. In lumber, which is subjected only to tension or compression, shake and splits do not affect strength as greatly.

The effects of checks and splits on strength and the principles of their limitation are the same as those for shake. Horizontal shear strength in a beam is dependent on the shearing strength of the particular species of wood and upon the extent of shake, check, and split present. In a beam with a split or shake down the length, a major portion of the shear stress is redistributed. The upper and lower halves of the split member then carries the portion. This “two-beam” shear action allows beams with shake and/or splits to carry loads which would appear to be too heavy in terms of horizontal shear strength.

The grading rules for shakes and splits are specific, with less of each allowed in the higher grades. Surface seasoning checks have a negligible effect on all strength properties and are not limited in dimension lumber grades. Below are just two examples.

Rules for No.1:

Checks – surface seasoning checks, not limited. Through checks at ends, limited as splits.

Splits – equal in length to width of the piece.

Shake – if through at ends, limited as splits. Surface shakes up to 2′ long.

Rules for No.3:

Checks – seasoning checks not limited. Through checks at ends, limited as splits.

Splits – equal to 1/6 the length of the piece.

Shake – surface shakes permitted. If through at edges or ends, limited as splits. Elsewhere through shakes 1/3 the length, scattered along the length.

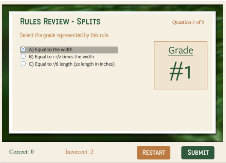

If you would like to memorize all of the rules for Shake, Splits and Check then take the SPIB eLearning courses for Dimension Lumber. Within these courses are rules memorizations and review drills that make it quick and simple for anyone to memorize any or all of the grading rules for 2″ dimension lumber.

These courses also have lessons with diagrams and explanations interpreting the rules and explaining in detail how to apply the rules to each grade and width of 2″ Dimension Lumber.

As a bonus SPIB also has a separate eBook with the Shorthand Rules guide and all the Total Measurement Limits for grading knots in Dimension lumber.

If you have any further questions, please feel free to contact us anytime!